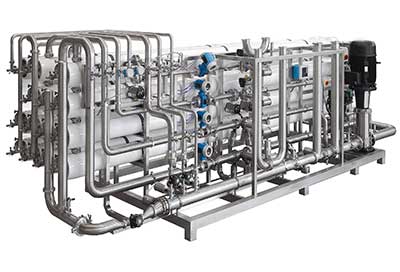

The pharmaceutical purified water system is divided into four parts: pretreatment, reverse osmosis system, storage and supply, sterilization and filtration.

Since the raw water contains suspended solids, organic matter, bacteria, colloids, microorganisms, etc., these substances will contaminate the reverse osmosis membrane during concentration and separation of the reverse osmosis system, making the system unable to work properly. Therefore, preliminary treatment must be carried out for the raw water, which includes the raw water tank and pump, multimedia filter, antifouling device, and precision filter.

Raw water tank

To provide stable water supply pressure to the reverse osmosis system, and to prevent the external water pressure from suddenly changing and affecting the stability of the entire system's operation.

Multi-media filter

It is a device that uses the mixed filtration function of several filtering media (such as quartz sand, activated carbon, anthracite, etc.) under certain pressure to filter the higher concentration of water through a certain thickness of granular or non-granular filtering material, effectively removing suspended solids and other impurities in the raw water to make the water clear. It can reduce the frequency of replacement of the precision filter.

Antifouling device

In order to prevent the scaling of calcium and magnesium ions on the surface of the reverse osmosis membrane during water concentration, antiscalant is added before reverse osmosis. It is an efficient liquid reverse osmosis dedicated antiscalant, used to control the inorganic scaling of pharmaceutical reverse osmosis systems, reduce the phenomenon of micro particle blockage.

Precision filter

In order to prevent suspended solids or small particles from entering the reverse osmosis system and blocking or breaking the reverse osmosis membrane, 5 μm precision filter cartridges are installed before the reverse osmosis equipment in the form of a cylindrical filter.

The outflow of the precision filter is pressurized by a first-stage high-pressure pump and enters the first-stage reverse osmosis system. After ultrafiltration through the reverse osmosis membrane, part of the water becomes first-stage pure water and enters the intermediate water tank, while the other part becomes concentrated water and is discharged. Ten reverse osmosis membranes are connected in series.

After the first-stage pure water is adjusted by pH, it enters the second-stage reverse osmosis system. The reason why pH value needs to be adjusted is that reverse osmosis can remove carbonate and bicarbonate but not CO2, and CO2 exists in water in the form of bicarbonate and gas. Therefore, the first-stage pure water is slightly acidic. Alkali can consume CO2 in pure water, making CO2 become carbonate and bicarbonate and be removed by the second-stage reverse osmosis membrane to meet the requirements of product water for pH value and resistivity.

At this time, the second-stage pure water is stored in the pure water tank. It consists of a first-stage high-pressure pump, a first-stage reverse osmosis membrane, an intermediate water tank, a pH adjustment device, a second-stage high-pressure pump, and a second-stage reverse osmosis membrane.

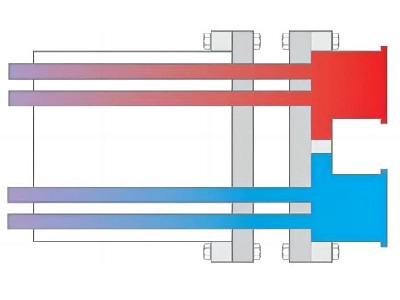

Semipermeable membrane: A thin film that selectively permeates substances is called a semipermeable membrane. Generally, a membrane that can only pass through the solvent but not the solute is called an ideal semipermeable membrane.

The second-stage pure water enters the pharmaceutical purified water systems, which are equipped with hydrophobic respirators, ozone generators, and other accessories. At this time, the second-stage pure water is first sterilized by ultraviolet rays and then sent to the pure water network through the terminal filter for circulation and use at various water points.

Before entering the supply pipe network, the second-stage pure water needs to pass through a high-power ultraviolet sterilizer to remove the bacteria bred during the storage of pure water, and finally through a terminal filter with a μm filter diameter to enter the supply pipe network. At the same time, according to regulations, the pure water tank and supply pipe network need to be regularly disinfected with ozone.